Price 89 आईएनआर/ Kilograms

MOQ : 100 Kilograms

Specification

- सीलिंग टाइप

- Rubber Gasket (if required)

- तापमान सीमा

- -20°C to +120°C

- सहनशीलता

- ±0.1 mm

- व्यास

- 25 mm – 300 mm

- कनेक्शन का प्रकार

- Welded / Threaded

- थ्रेड टाइप

- BSP / NPT

- यील्ड स्ट्रेंथ

- 205 MPa (min)

- फ्लेक्सिबिलिटी

- Rigid

- टेन्साइल स्ट्रेंथ

- 520 MPa (min)

- कोटिंग का प्रकार

- No Additional Coating

- प्रॉडक्ट टाइप

- मटेरियल

- कनेक्शन

- शेप

- स्टैण्डर्ड

- सतह का उपचार

- बाहरी व्यास

- 25 mm – 300 mm

- अनुभाग आकार

- लम्बाई

- Up to 6 meters

- मोटाई

- 1.5 mm – 6 mm

- रंग

- gray

- उपयोग

- Water Filtration, Drainage System, Borewell

- रेटेड प्रेशर

- 6 bar – 16 bar

- सामग्री ग्रेड

- SS 304 / SS 316

- एप्लीकेशन

- Slot Open Area Percentage

- Up to 22%

- Pipe End Type

- Plain, Beveled or Threaded

- Slot Length

- 10 mm – 100 mm

- Production Process

- Seamless / ERW

- Slot Pattern

- Straight or Staggered

- Slot Width

- 0.5 mm – 3 mm

- Corrosion Resistance

- Excellent

- Minimum Order Quantity

- 100 टुकड़ाs

- Packing Type

- Plastic Wrapping or Wooden Box

Trade Information

- Minimum Order Quantity

- 100 Kilograms

- भुगतान की शर्तें

- , , ,

- आपूर्ति की क्षमता

- प्रति सप्ताह

- डिलीवरी का समय

- दिन

- पैकेजिंग का विवरण

- As per requirement.

- मुख्य निर्यात बाजार

- , , , , , , , ,

About

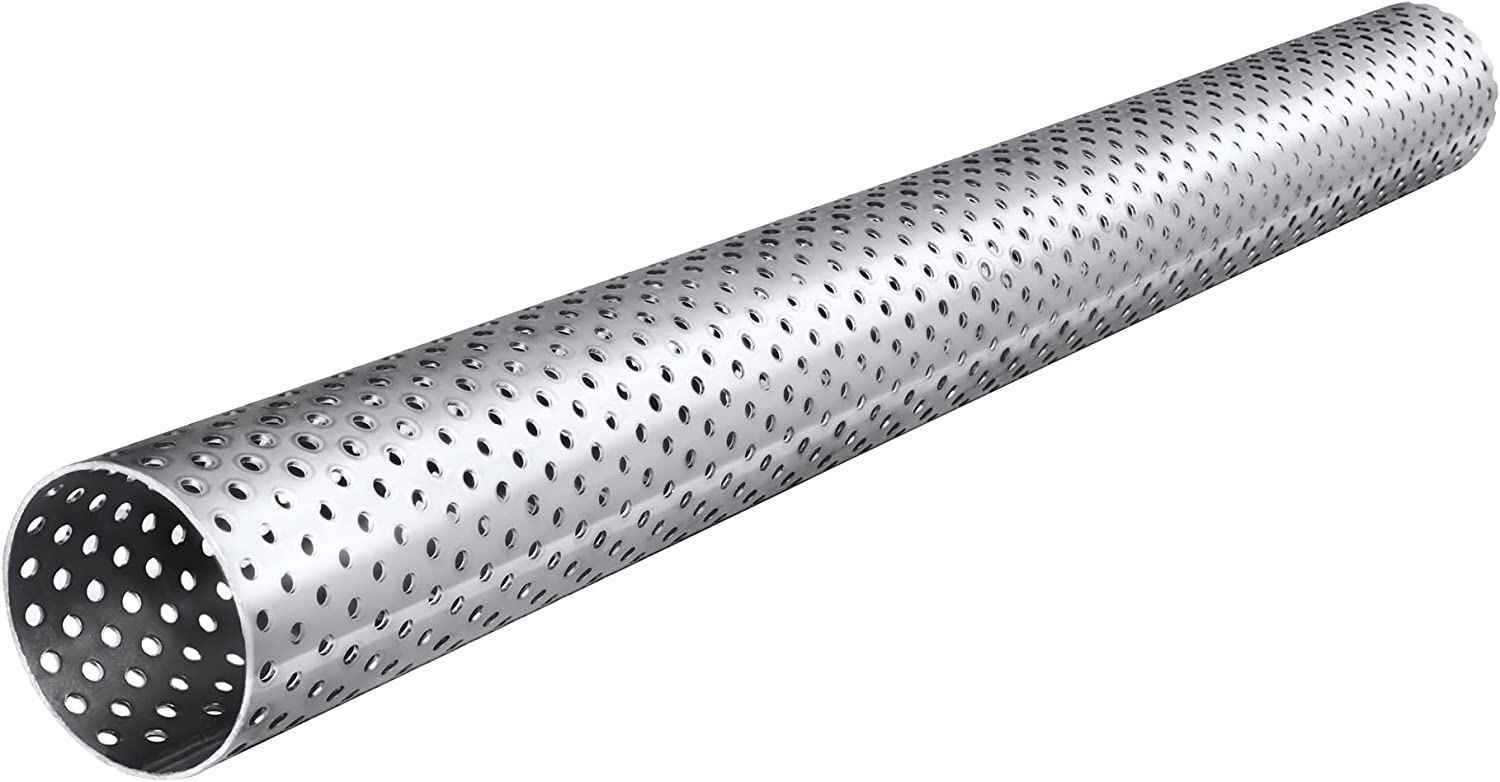

Screen pipes or Slotted pipes are used for casing in the groundwater section to allow water to enter the well. These pipes can also be used to provide soak-ways for the stormwater/rainwater to infiltrate back into surrounding areas. Thus, we can recharge the groundwater and prevent the runoff of rainwater.Precision-Engineered Slotted Pipes

Our slotted pipes are meticulously designed for maximum filtration efficiency and outstanding longevity under demanding conditions. Their precision-engineered slots, available in straight or staggered patterns, and customizable slot widths provide optimal open area percentage for diverse applications like water filtration, drainage systems, and borewells. Made from high-quality stainless steel and polished for a refined finish, these pipes guarantee excellent corrosion resistance and structural integrity even in harsh environments.

Versatile Applications Across Industries

Engineered to serve multiple sectors, our slotted pipes perform reliably in industrial, agricultural, and construction settings. With a robust design and customizable features-including a wide range of diameters, lengths, and connection types-they adapt seamlessly to project-specific requirements. The pipes' rigid construction and high-pressure rating make them a preferred choice for sustainable and efficient fluid management across a variety of operational demands.

FAQ's of Slotted Pipes:

Q: How are the slot patterns and widths selected for specific applications in slotted pipes?

A: Slot patterns (straight or staggered) and widths (0.5 mm to 3 mm) are chosen based on the filtration level required and the particle size to be excluded. Straight patterns offer uniform flow, while staggered patterns improve strength and distribution. Our technical team can help recommend the most suitable configuration for your application.Q: What is the production process for these slotted pipes, and how does it impact quality?

A: The slotted pipes are manufactured via seamless or ERW (Electric Resistance Welded) processes. Seamless pipes offer superior strength and uniformity, while ERW pipes provide cost-effective precision. Both processes adhere to ASTM A312/A213 standards, ensuring high structural integrity and dimensional accuracy.Q: When should stainless steel slotted pipes with excellent corrosion resistance be used?

A: These pipes are ideal for environments where exposure to water, chemicals, or corrosive substances is anticipated. Common usage includes water filtration, drainage systems, and borewells, as well as any application that demands long service life and minimal maintenance in challenging settings.Q: Where can these slotted pipes be installed or applied?

A: They are suitable for installation in industrial plants, agricultural irrigation systems, building construction drainage, borewells, and water management facilities. Their robust design and flexible connection options ensure compatibility with a wide range of infrastructures.Q: What are the main benefits of using slotted pipes with up to 22% open area?

A: A high open area (up to 22%) ensures enhanced filtration efficiency while maintaining structural strength. This feature allows for higher flow rates and reduced clogging, making these pipes particularly effective for water extraction, drainage, and filtration systems.Q: How is the packing and delivery of slotted pipes managed for safe transportation?

A: Pipes are packed using plastic wrapping or placed in wooden boxes, depending on project requirements. This robust packing system prevents surface damage and ensures the pipes reach their destination in optimal condition, ready for immediate installation.Q: What connection and thread types are available for these pipes?

A: Customers can choose from plain, beveled, or threaded ends, with BSP or NPT thread options. This flexibility allows easy integration with existing piping networks, using either welded or threaded connections to suit various installation needs.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें